Wholesale Temperature Resistant Fabric from Leading Manufacturers and Factories

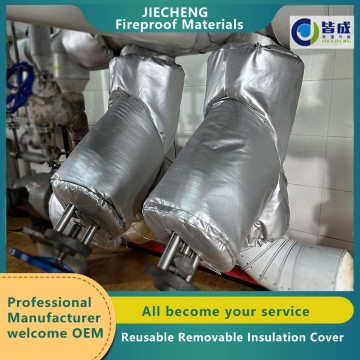

When it comes to sourcing high-quality temperature resistant fabric, I’ve found that Jiangxi Jiecheng New Materials Co., Ltd. stands out in the market. Our fabrics are designed to withstand extreme conditions, making them ideal for a variety of applications, from industrial use to specialized clothing, As a manufacturer and supplier, we pride ourselves on offering wholesale options that meet the diverse needs of our B2B clients. Whether your business is in need of large quantities for production or looking for a reliable partner to supply premium materials, we got you covered

7 Key Tips To Temperature Resistant Fabric Service Factory

In the ever-evolving landscape of high-temperature insulation solutions, Jiangxi Jiecheng New Materials Co., Ltd. stands out as a premier manufacturer offering top-tier temperature resistant fabrics. As a global purchaser looking for reliable partners, knowing how to evaluate and select a fabric service factory is crucial. Here are seven key tips to help you navigate this process. First, prioritize factories with extensive experience in producing high-temperature insulation products, specifically those specializing in detachable thermal insulation sleeves and insulation boards. Expertise not only ensures quality but also provides insight into innovative technologies that can enhance the performance of Insulation Materials. Secondly, investigate the factory's certification and compliance with international standards. A factory that adheres to stringent quality control measures demonstrates a commitment to reliability, which is essential for high-temperature applications. Moreover, assess the flexibility and customization options offered by the factory. The ability to tailor products to meet specific project requirements can significantly impact insulation effectiveness. Additionally, evaluate their supply chain management to ensure timely delivery and consistent product availability. Lastly, consider the factory's customer support and after-sales service; a responsive and knowledgeable team can make a substantial difference in your purchasing experience. By focusing on these critical aspects, you can establish a partnership with a fabric service factory that not only meets your technical needs but also contributes to the overall success of your projects in high-temperature environments.

7 Key Tips To Temperature Resistant Fabric Service Factory

| Tip | Description | Material Type | Temperature Range (°C) | Common Uses |

|---|---|---|---|---|

| 1. Choose the Right Fibers | Select fibers known for heat resistance. | Aramid, PBI | -200 to 200 | Firefighter gear, industrial protection |

| 2. Assess Coating Options | Consider coatings that enhance temperature resistance. | Silicone, PTFE | -50 to 300 | Industrial fabric, protective clothing |

| 3. Focus on Weave Structure | Utilize tight weaves to enhance durability. | Fiberglass, Kevlar | -200 to 430 | Welding blankets, heat shields |

| 4. Test for Fade Resistance | Ensure materials retain color and integrity under heat. | Polyester, Nylon | -20 to 180 | Outdoor gear, uniforms |

| 5. Consider UV Protection | Integrate UV-protective elements in fabric. | Acrylic, SCOTCHGARD | -30 to 150 | Camping gear, outdoor furniture |

| 6. Analyze the End-Use Environment | Evaluate the conditions the fabric will face. | Various blends | Varies | Automotive, aerospace |

| 7. Invest in Quality Testing | Conduct rigorous testing for performance verification. | All types | -200 to 600 | Critical applications in various industries |

Top-Rated Temperature Resistant Fabric Your Trusted OEM Partner Pioneers in the Field

M

Michael Bradford

The quality of the product exceeded my expectations. The team was very accommodating and their service was top-notch.

07 June 2025

C

Chloe Wilson

Wonderful experience! The product is superb, and the after-sales service was incredibly helpful.

16 May 2025

E

Ellie Davis

Wonderful product! I appreciate the professionalism of the after-sales team.

21 May 2025

N

Nadia Garcia

Excellent item! Their support staff were incredibly friendly and knowledgeable.

01 June 2025

S

Sophie Weber

Awesome experience! The product is solid and the service team was very professional.

11 June 2025

W

Wyatt Lee

Impressive quality! I appreciate the professionalism of the customer support staff.

09 June 2025