Removable industrial insulation cover

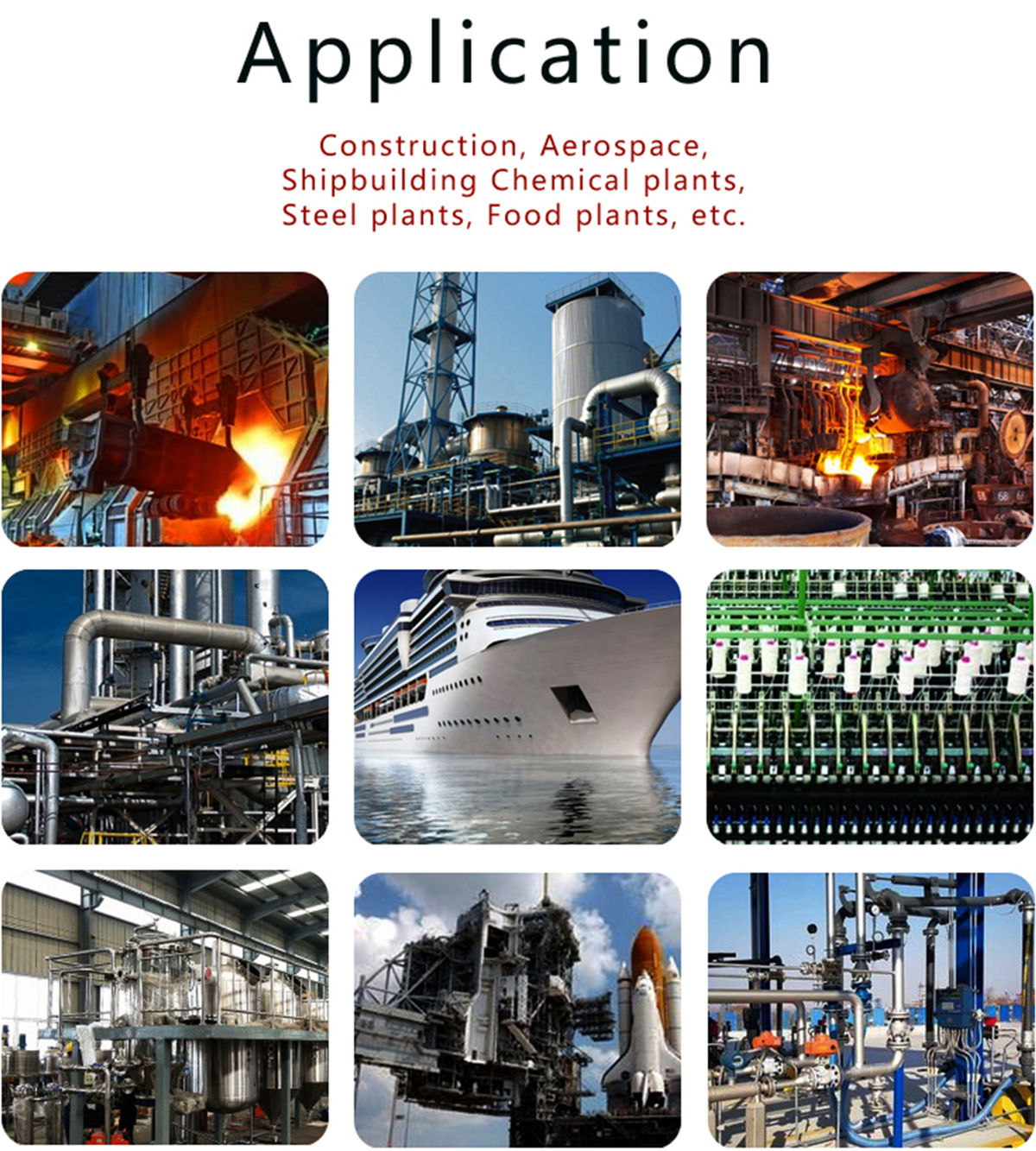

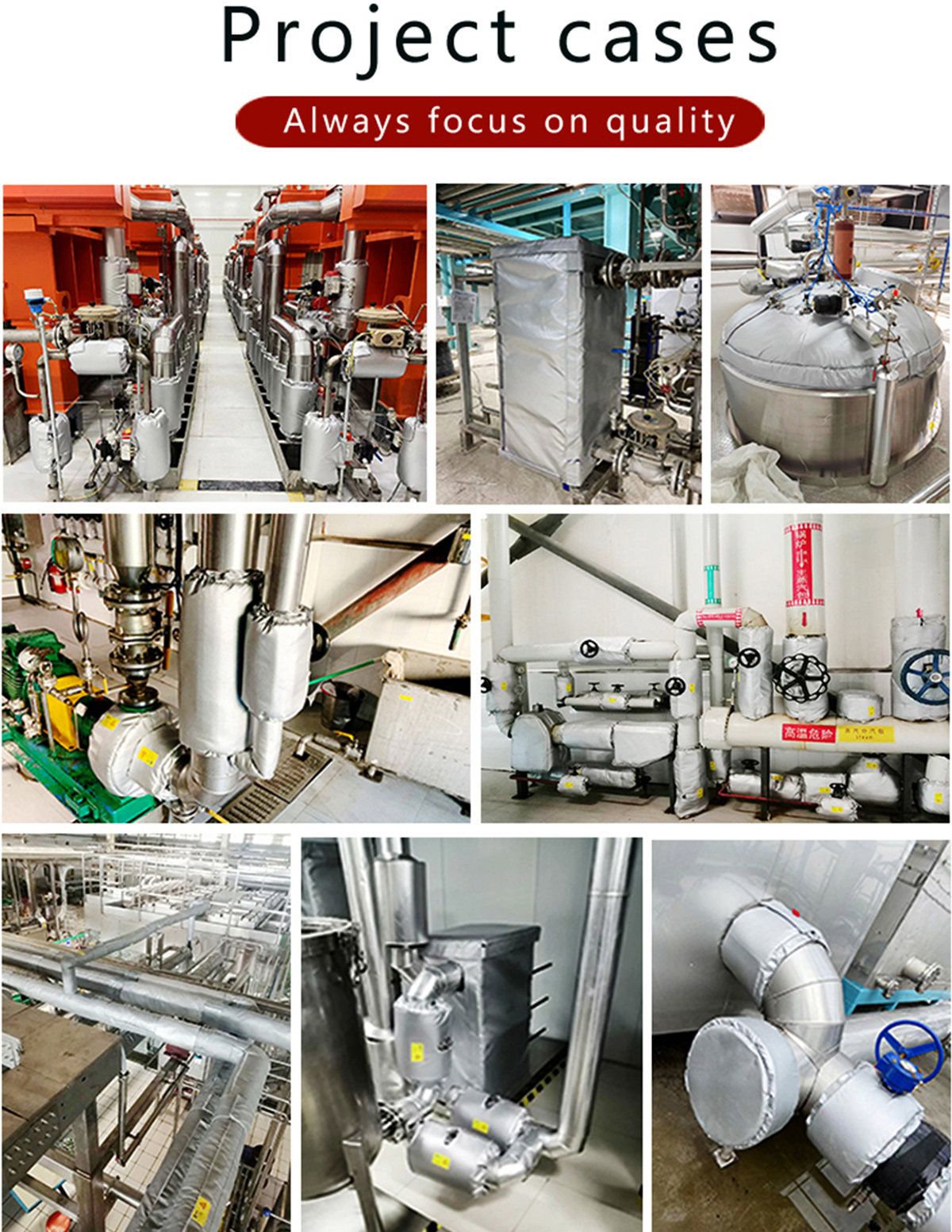

wide range of applications

Removable insulation jacket can be used in different fields; such as breweries, beverage factories, food factories, chemical factories, pharmaceutical factories, ships, industrial robots and so on.

Removable thermal insulation jacket (industrial thermal insulation jacket) which is more widely used is the reaction kettle thermal insulation jacket, electric accompanied by heat (electric heating) thermal insulation jacket, shipyard (ship valve) thermal insulation jacket, injection molding machine (gun barrel) thermal insulation jacket/cover, manhole, heterogeneous thermal insulation jacket and so on.

Thermal insulation performance comparison

|

Project |

Aerogel detachable |

Traditional insulation |

|

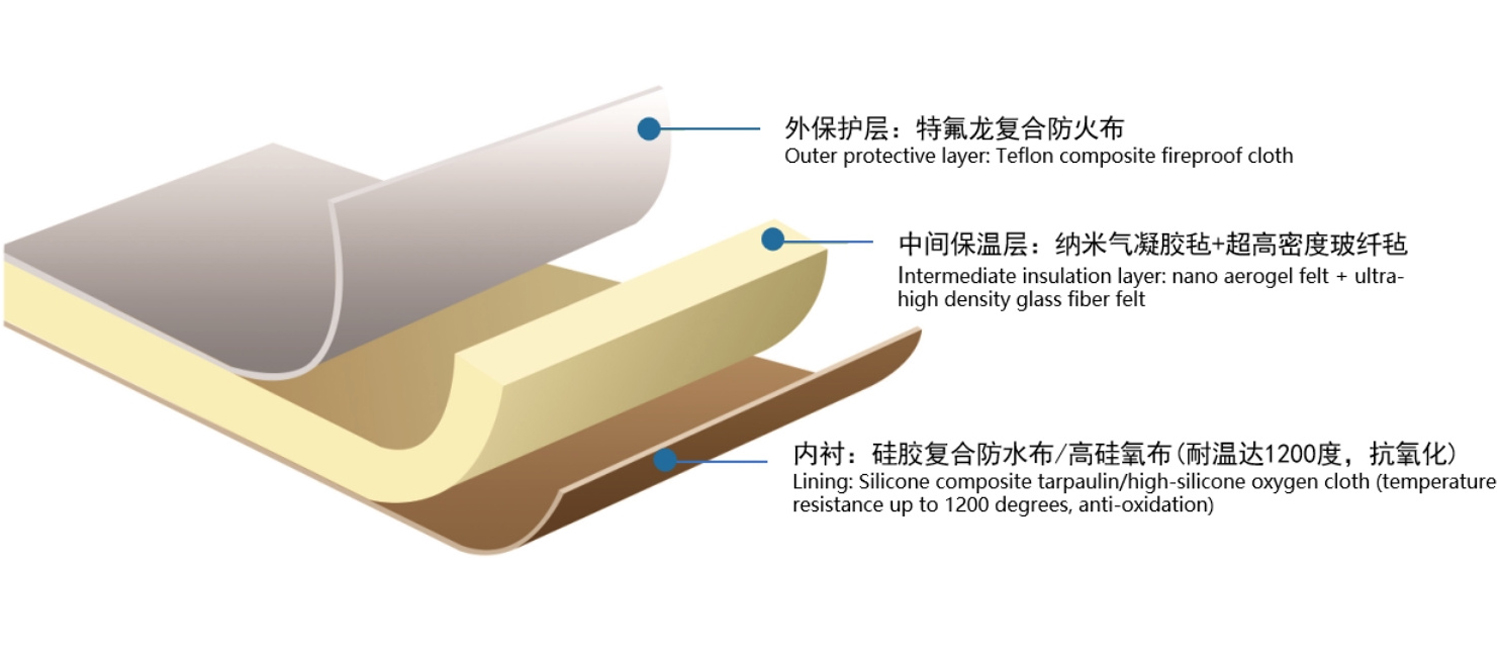

texture |

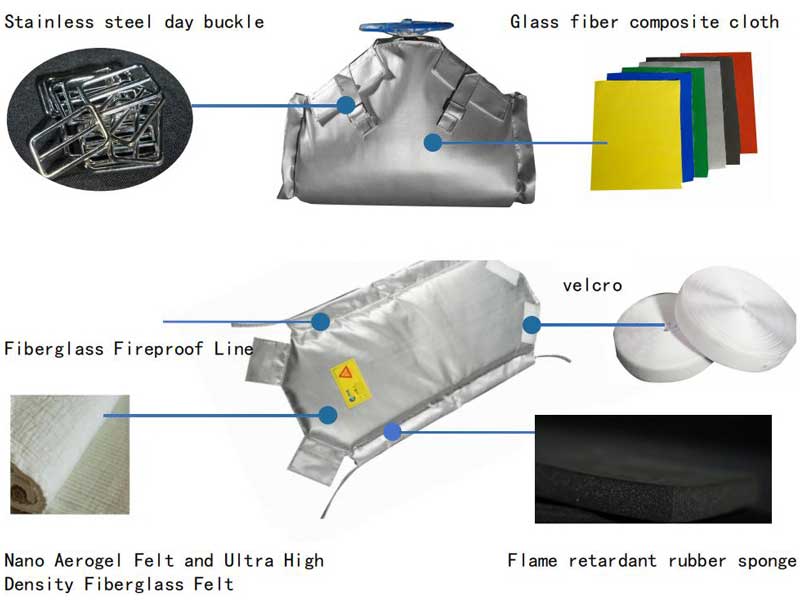

Outer protective layer: silicone composite fireproof cloth (fireproof, waterproof, oil proof, acid and alkali resistant, corrosion resistant) |

Outer protective layer: galvanized iron sheet (not corrosion resistant, oil, easy to transfer heat, easy to deformation, low repetition rate, appearance is not beautiful) |

|

Intermediate insulation layer: nano aerogel + glass fiber felt (nano aerogel is the best insulation effect at present, considering the cost, the combination of the two has achieved the best insulation effect.) Non-toxic and asbestos-free. |

Intermediate insulation layer: rock wool, asbestos, rubber and plastic, etc. |

|

|

Lining: silicone composite fireproof cloth/high silica cloth (maximum temperature resistance of 600 degrees, strong oxidation resistance) |

Lining: None |

|

|

thickness |

According to the equipment temperature of 25-30mm, there is room for pipeline layout or later transformation |

100-150mm, occupy too much space of the pipeline layout, the pipeline due to the small gap between the insulation pipes, the later transformation is difficult |

|

heat conductivity coefficient |

0.017~0.023w/m·k (for heat insulation, the smaller the thermal conductivity, the better) |

0.04w/m·k |

|

construction |

1, disassembly, installation is very convenient, can be reused, do not need to ask professionals; 2, 100 square meters of insulation area, calculated by 6 people: demolition 2 hours, installation 1 working day; The maintenance equipment can be disassembled in sections at any time. |

1, disassembly and installation is not convenient, generally need to ask professional personnel; 2, 100 square meters of insulation area, calculated by 6 people: one working day demolition, 5-7 working days installation; The overall molding and disassembly are bulky |

|

environmental suitability |

Strong adaptability: acid and alkali resistance, the product appearance is beautiful and clean, the surface can be scrubbed and so on. |

The galvanized iron sheet commonly used in the shell is not resistant to acid and alkali, and will sink after the surface is bumped, and the appearance is no longer beautiful and cannot be scrubbed. |

|

environmental protection |

No pollution, free of asbestos and any other harmful substances. |

Products contain asbestos, glass wool and other harmful substances, pollution, not environmental protection |

|

range of application |

Strong flexibility, non-standard equipment can be customized, wide range of application. |

There are limitations, special-shaped equipment, small space can not do insulation. |

|

energy conservation |

More than 30% energy saving than traditional thermal insulation materials |

/// |

|

payback time |

使Long life: indoor 20 years, outdoor 15 years, within a year can recover the cost of buying insulation. One investment, many years of returns. |

It should be replaced after each overhaul, and the life is generally about 1-2 years. In the long run, the cost input is more expensive than the new insulation. |

|

cost of investment |

The one-time investment cost is about 20-30% more than traditional insulation |

/// |

Inquire Now!

For inquiries about our products, please leave your email to us and we will be in touch within 24 hours.